Vendita di Vino, Spumante e Grappa online

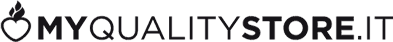

ALEMBIC Alembic is divided into two categories: continuous and discontinuous.

CONTINUOUS ALEMBIC allow a distillation with no interruptions. All the process is carried out in one time using a two columns alambic. The process of distillation begins by filling the boiler with the raw matter which will be subsequently heated. The distillation process allows the evaporation of many substances, including the ones having negative organoleptic qualities and that will be eliminated in order not to compromise the qualities of the distillate. This operation is called cut of heads and tails.

DISCONTINUOUS ALEMBIC implies an intermittent alimentation of the distiller in which the pomace is loaded, processed and then it is re-loaded with new pomace. Using discontinuous alembic the process is repeated many time in order to obtain a high quality product.

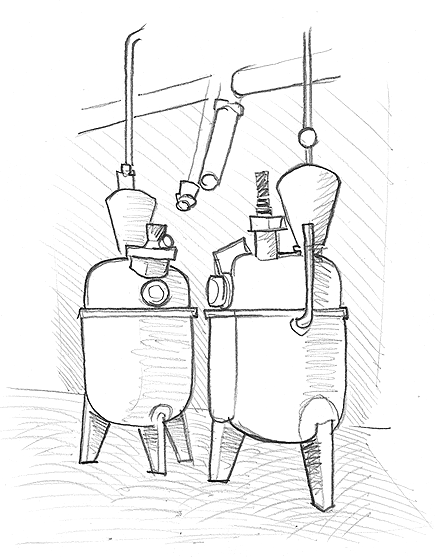

Alembic is composed by four elements which determine the process’ phases: the heat source, usually made by cooper or stainless is used to contain the liquid to be distilled; the cover, in which takes place on the condensation of the steam and serves to select the alcoholic vapors; the swan neck, which transports the vapors from the boiler to the cooler; the cooler, contained in a container filled with cold water or other cooling liquids. It serves to condense the alcohol vapors from which the distillate is obtained.

Discontinuous alembrics, depending on the heat source and on the way the heat is transmitted to the matter to be distilled, can be divide in three categories: direct heat, almost disappeared; water bath, represent a minority of the plants; steam operated boilers, the most frequently used and, with over 50 operating installations. |

|